Predict Faults and Prevent Downtime

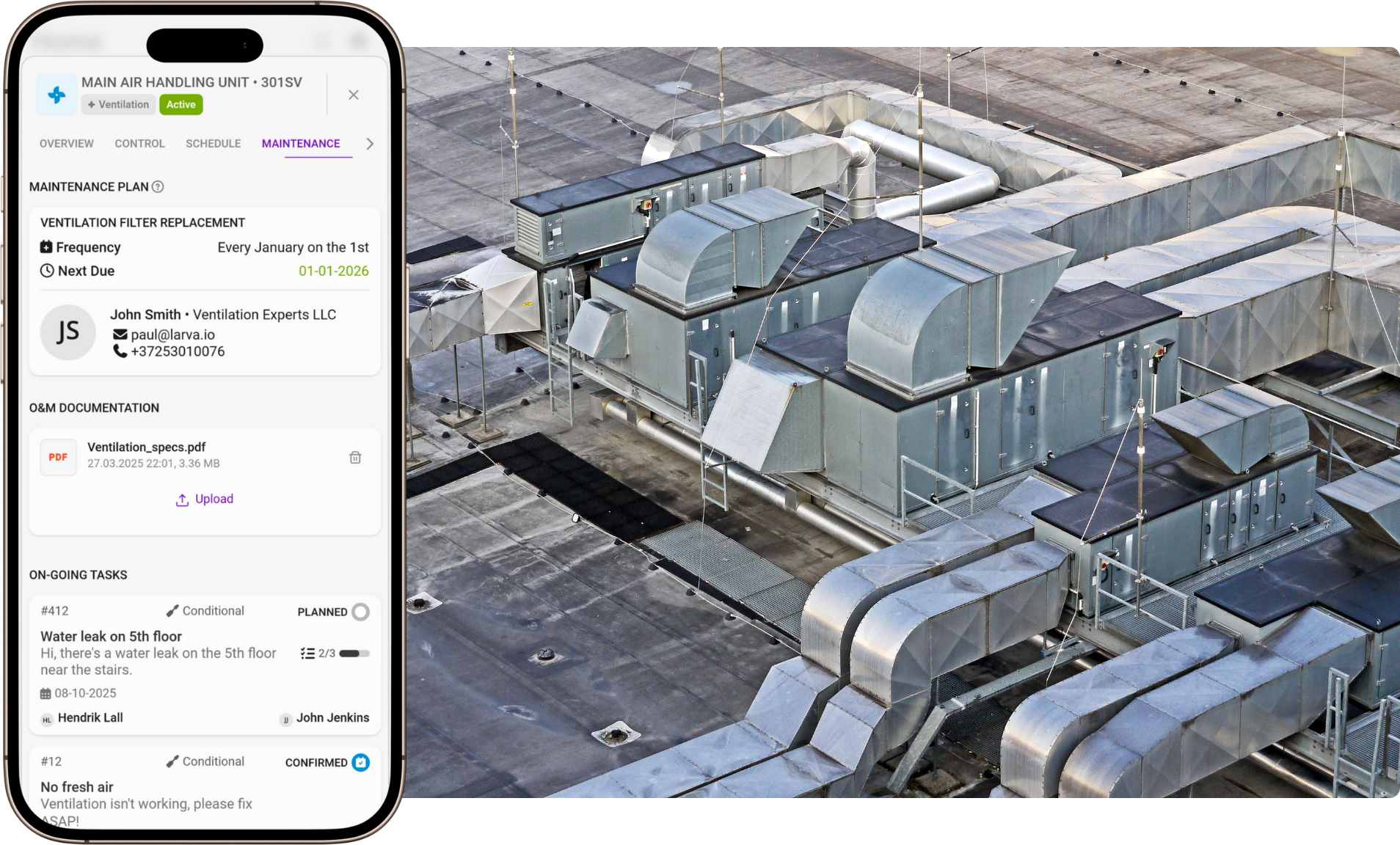

Move from calendar checkups to condition-based care. Plan recurring PMs (Preventive Maintenance), watch sensor drift, and schedule the right crew with parts and access before small issues turn into costly repairs or tenant complaints.

How It Works

Connect & Import

Link BMS points, meters and alarms, sync assets from your CMMS (or create them in Fentrica), and map PM templates, checklists, readings and parts.

Set Rules & Triggers

Create recurring PMs with owners and due dates, add condition triggers from run-hours and sensors, enable machine learning drift detection and choose routing, deadlines and approvals. Optional: auto-issue time-boxed access for vendor jobs.

Run, Review & Improve

Alarms and drifts become tickets with diagnostics, procedures and parts. Resolve most issues remotely; use mobile checklists onsite. Dashboards track response/resolve times, first-visit fix rate and repeat faults. Everything lands in the digital logbook and exports to BI/ERP.

Why Teams Use Fentrica for Preventive & Predictive Maintenance

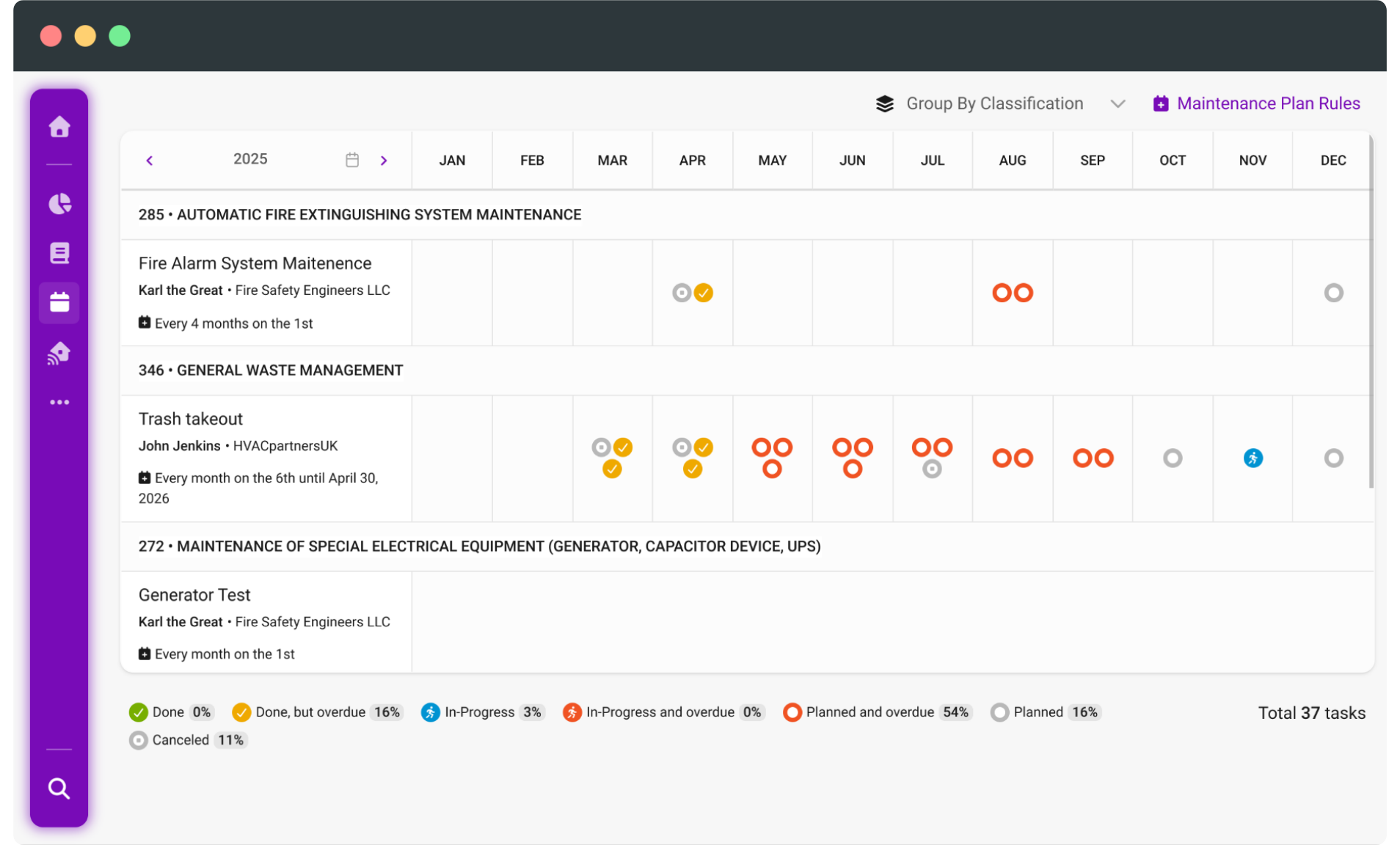

PM schedules that stick

Plan recurring maintenance with clear owners, due dates and checklists, then balance workload so nothing slips.

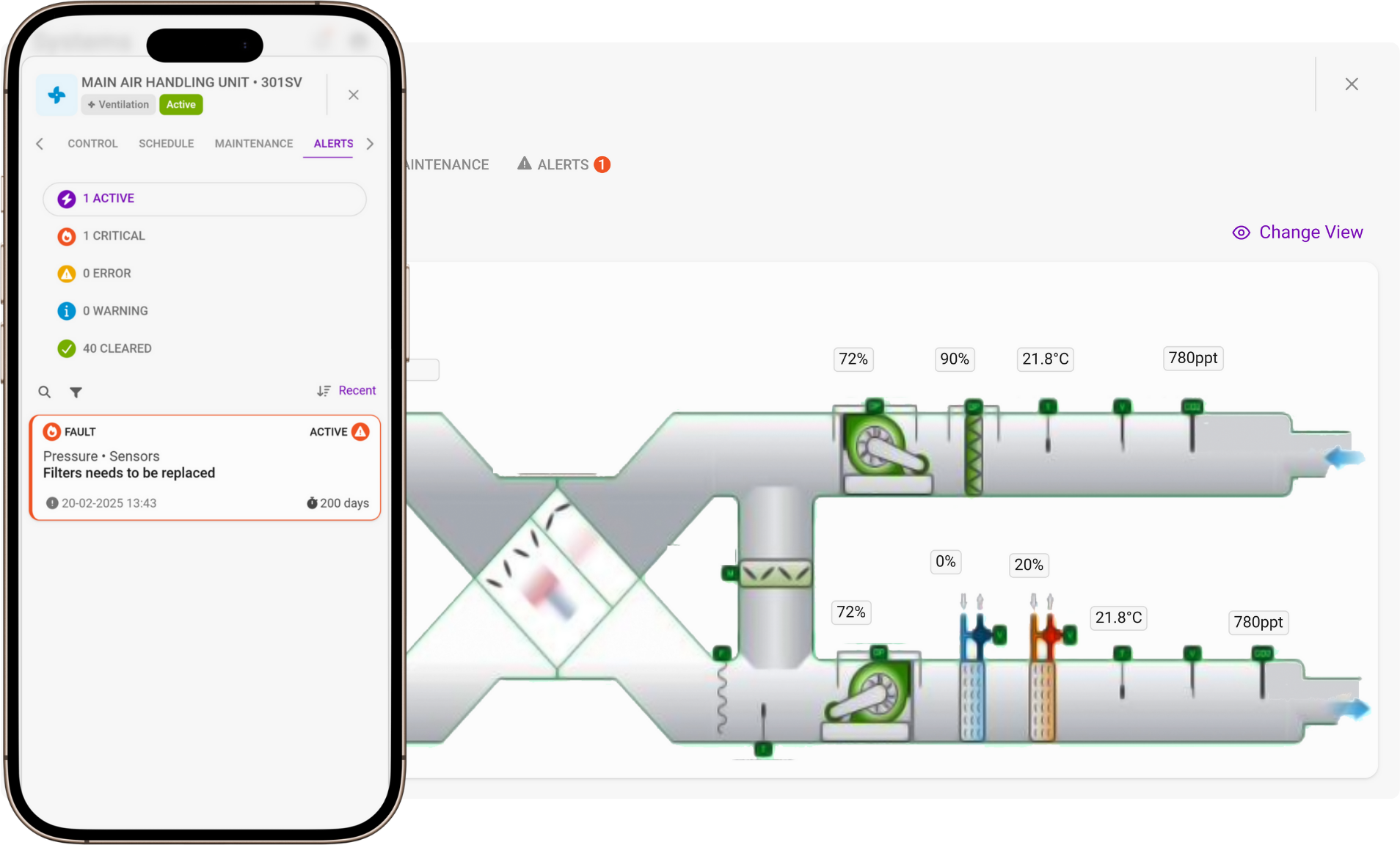

Condition-based and predictive triggers

Create tasks from meter readings, run-hours and sensor thresholds while machine learning flags even as little as 3% efficiency drift before failures -> details the human eye doesn't even notice.

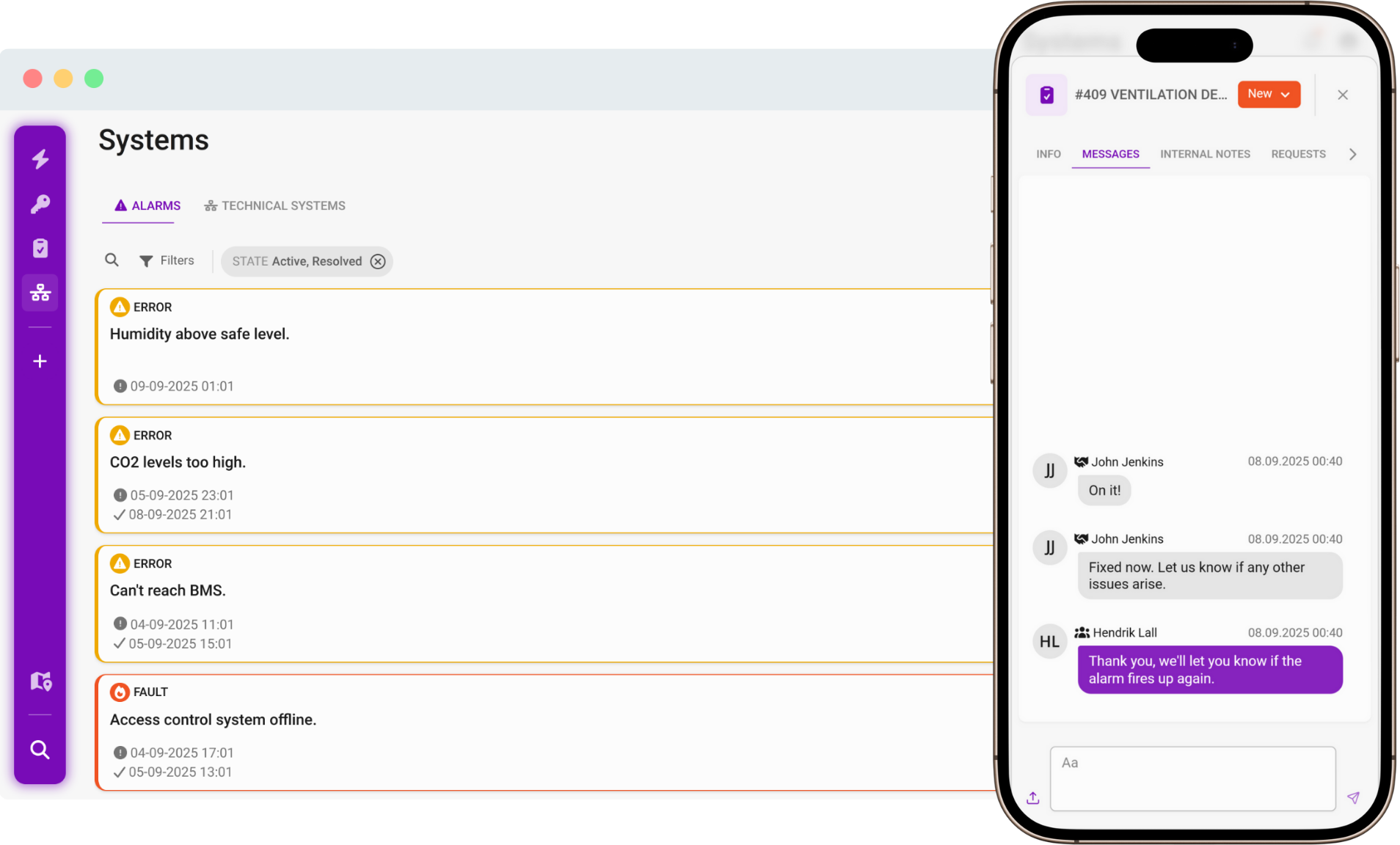

Smart, centralized alarms

Handle all alarms from one inbox that de-duplicates bursts, groups related alerts and prioritizes by cost, comfort and risk.

Resolve most issues remotely

Close the majority of tickets without a site visit using live points, safe control and guided steps for tenants or vendors.

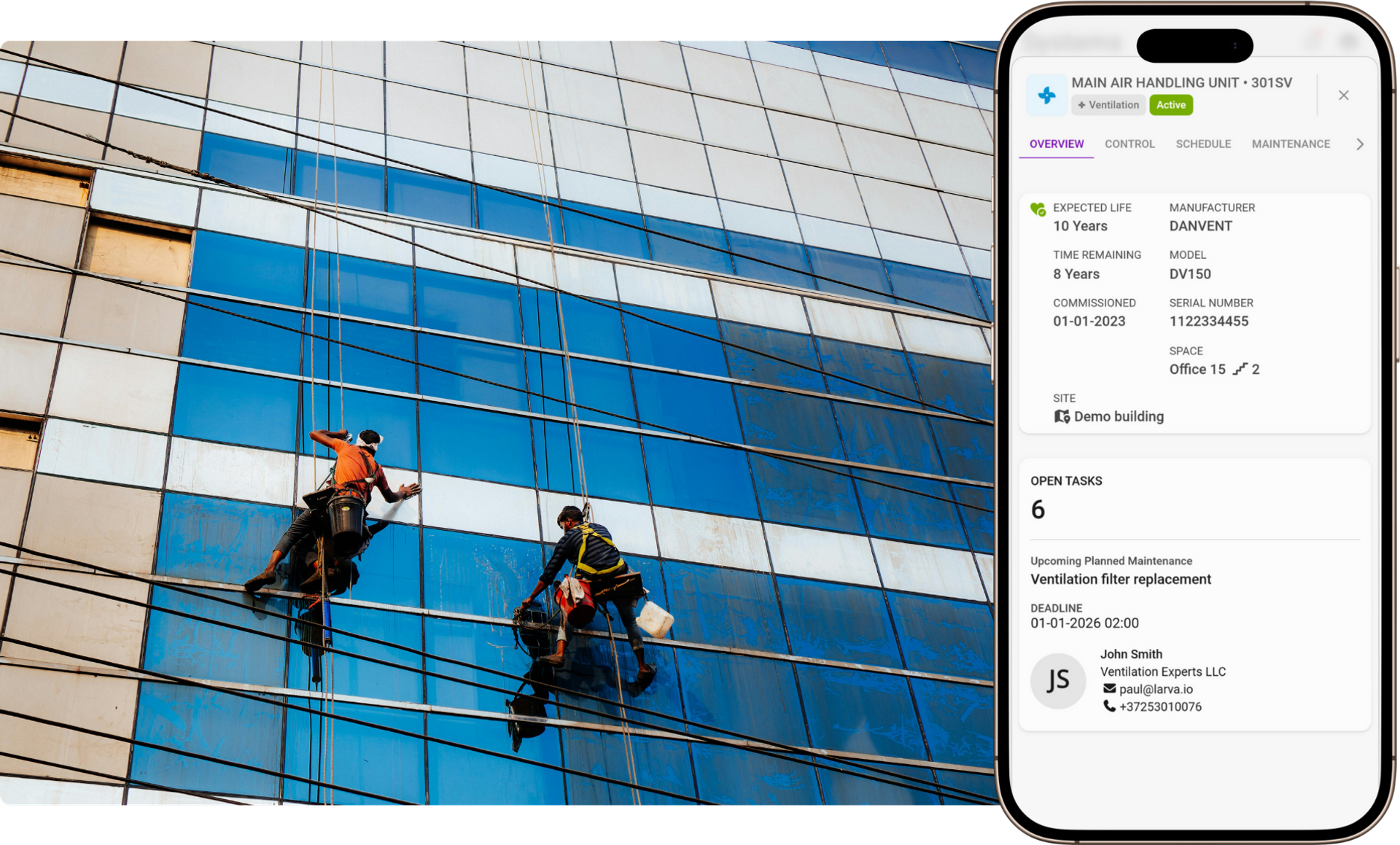

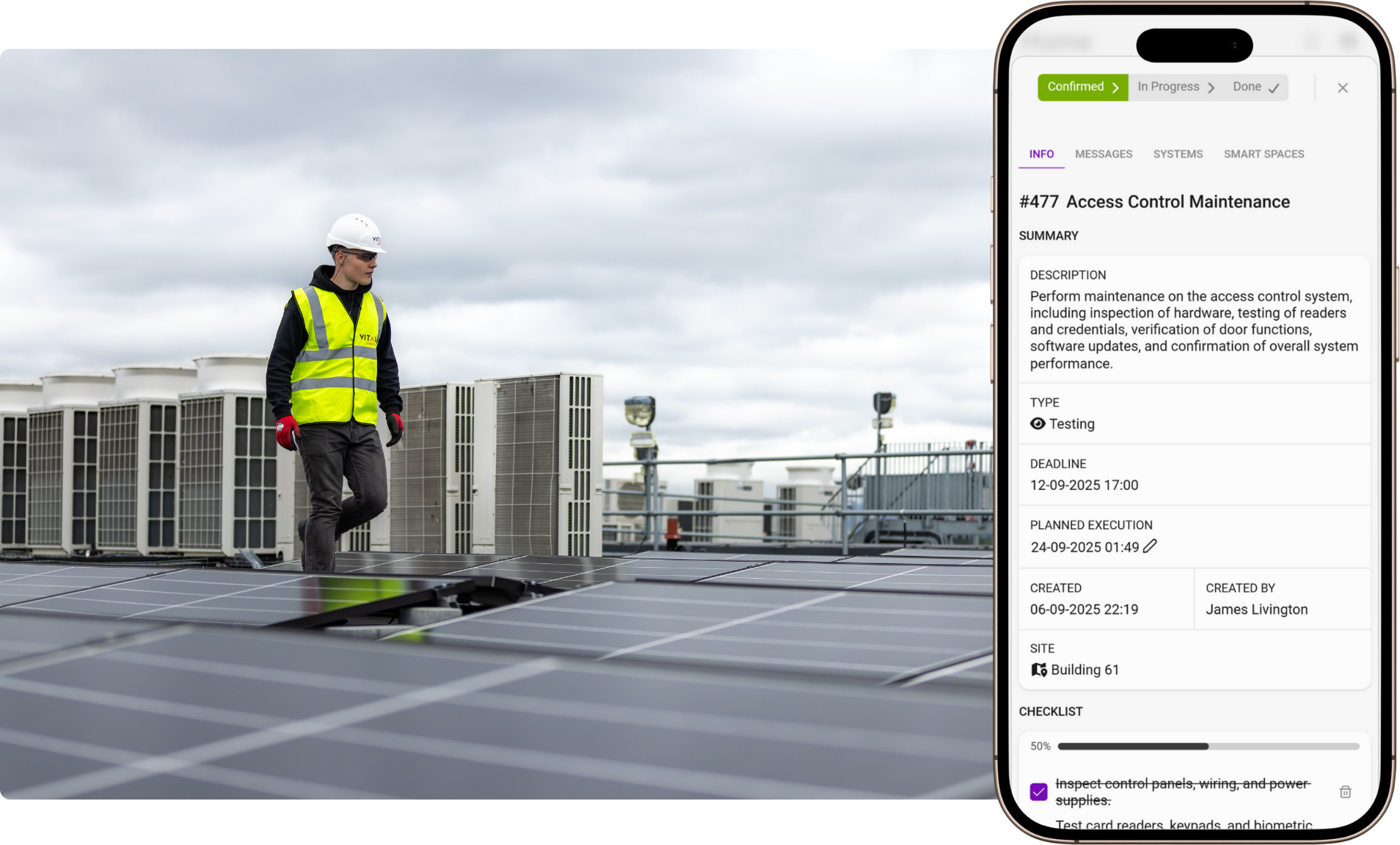

First-visit fixes when onsite

When a visit is needed, techs arrive prepared with diagnostics, procedures, parts lists and a time-boxed door pass.

Extend asset life and protect warranties

Reduce stress events and prove PMs with a digital logbook that ties photos, readings and actions to each asset.

Capabilities at a Glance

Recurring PM plans by asset, site and season

Run-hour counters and condition triggers

Smart aggregation alarms, cross-system correlation, leak & fault detection, conflict detection (heating vs cooling), impact-based prioritisation.

Mobile checklists with photos and readings

AI root cause analysis and model procedures in each task

Vendor calendars, deadlines and escalations

Digital asset logbooks with search and exports

Links to access passes and tenant updates

Integrates with BMS, business software and all your hardware

FAQs

Preventive = planned checklists and OEM/run-hour intervals. Predictive = live signals plus smart aggregation. We correlate BMS points, meters and other data to detect drift, leaks, sensor faults and heat vs cool conflicts, then prioritise by impact and open a ticket before failure.

You get CMMS-grade maintenance with AI enhancement + tighter links to access, energy and reporting. We can also integrate with an existing CMMS if required.

BMS alarms trigger on individual points. Fentrica connects points across systems, explains likely root causes and ranks issues by cost, comfort and risk so teams act where it matters most.

It’s multi-signal correlation across HVAC, meters and sensors. Instead of single thresholds, we combine evidence to uncover hidden issues like leaks, stuck valves, failing sensors or systems fighting each other.

No! That's where the uniquness of Fentrica comes in. We can connect with almost anything, make it smart and tie it together with everything else in your buildings.

Usually not. We use the points you already have from BMS and meters. Where needed, we can read simple add-on sensors.

Remote points, safe restarts, setpoint changes and vendor pre-diagnosis close most tickets without a truck roll. Onsite visits get a time-boxed door pass.

Models learn normal behavior per asset, compare against history and peer assets, and flag 1–3% efficiency drift, leaks and conflicts with likely causes.

Most sites go live in about 30 days after asset mapping and rule setup.

Yes. SSO level security, encrypted data in transit/at rest, full audit trail.

Let's talk about your buildings

Siduri 3, 11313 Tallinn, Estonia